STS Aerospace offers extensive design capabilities, specializing in PTFE flexible hose, annular convoluted metal hose, rigid tube fabrication, and flex-rigid assemblies. Our engineers have extensive product and customer knowledge, and utilize the latest tools and technology, ensuring we meet all your fluid transfer design needs. We can provide you with solutions for complex product design from concept to qualification.

Engineering Capabilities

Research & Development

R&D is a pivotal part of our continuous engineering processes. R&D activities include various design and testing with a dedicated engineering teams who see themselves as business partners who go beyond problem solving and focus on problem prevention.

Research & Development

Tool Design & Build

Tools can be designed to manufacture a specific custom product or manufacturing process. If a tool does not exist, we can make it easily and quickly while ensuring a quality end-product is delivered. As a result, we can make products faster, which is critical in an R&D environment.

Tool Design & Build

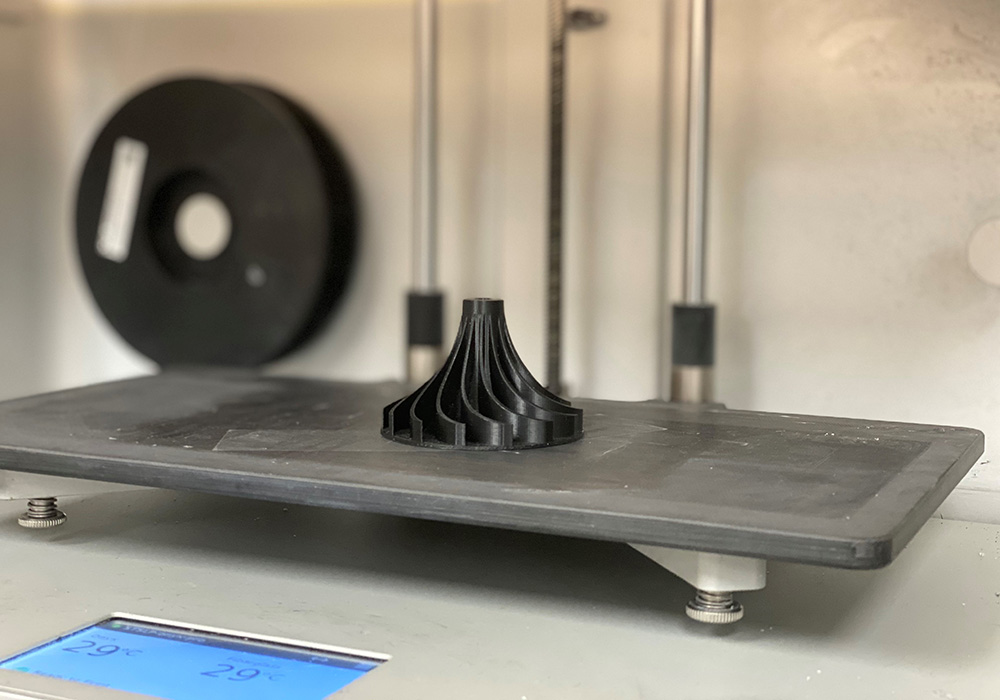

3D Modeling & Additive Manufacturing

Engineered product solutions can be designed in-house on customized software. We also offer prototype, PPAP, or first issue products to our customer as they work through design and innovation of their new design. Throughout the prototype process, we will ensure a high-quality product that meets manufacturability standards.

3D Modeling & Additive Manufacturing

Engineering Technologies

We recognize the ever-changing technology required to interface with your programs and file types, and we have the engineering staff ready to support your manufacturing requirements. CATIA file translation capabilities include all possible software.

Our engineering and design technologies include:

- IGES, STEP, UG Translators

- 3D Wire Frame & Solid Modeling

- Tool, Jig & Fixture Design

- Product Design & Qualification

- CATIA V4 R4.4

- CATIA V5 R19

- Unigraphics NX8.5 CAD System

- Reverse Engineering

- LaserVision

- Romer

- CMM

- Accredited Environmental Test Lab (ISO 17025)

- 3D Plastic Printing Capability