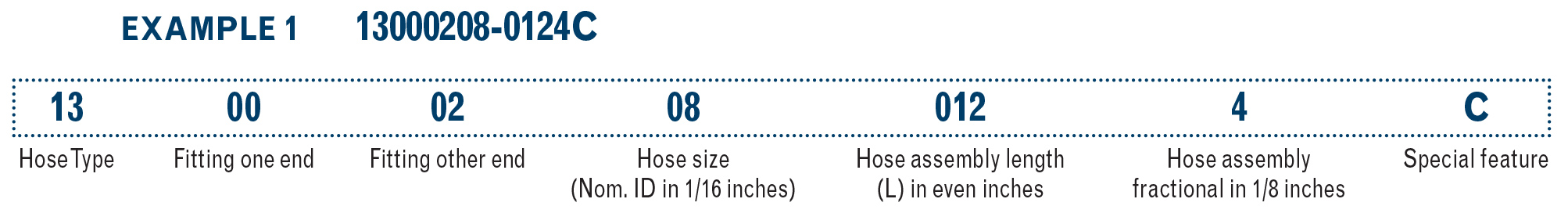

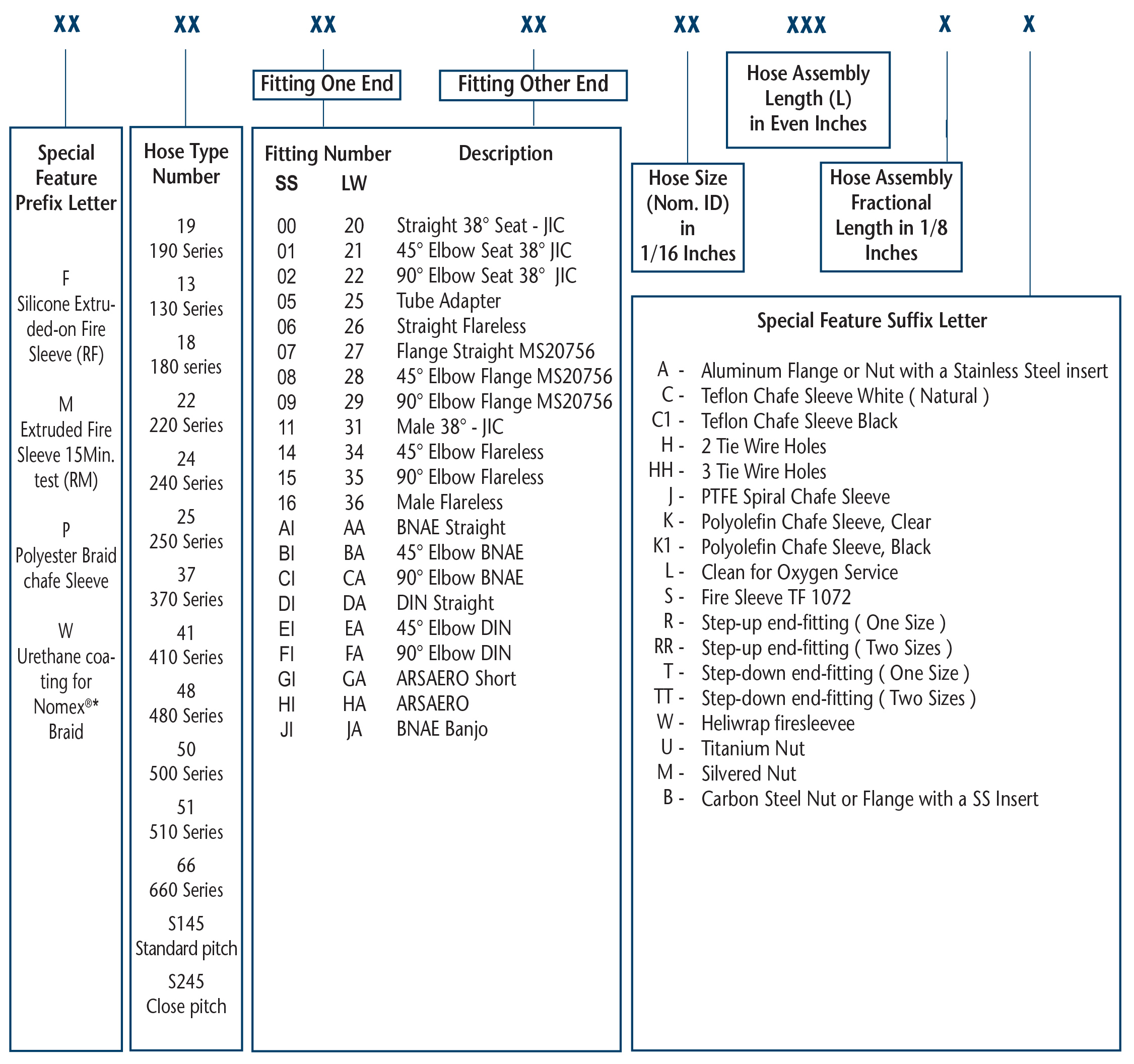

2. Double Elbow Configuration

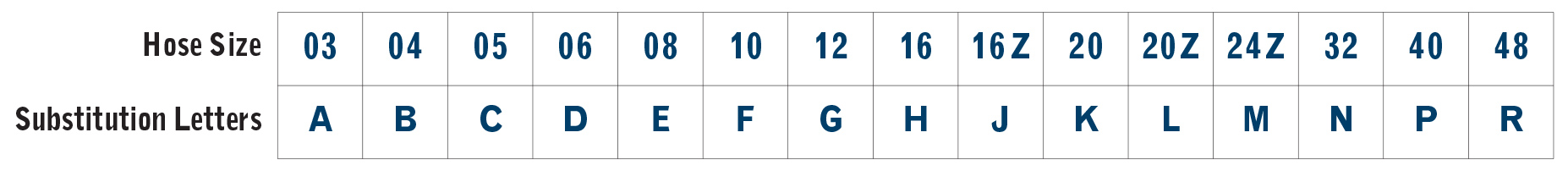

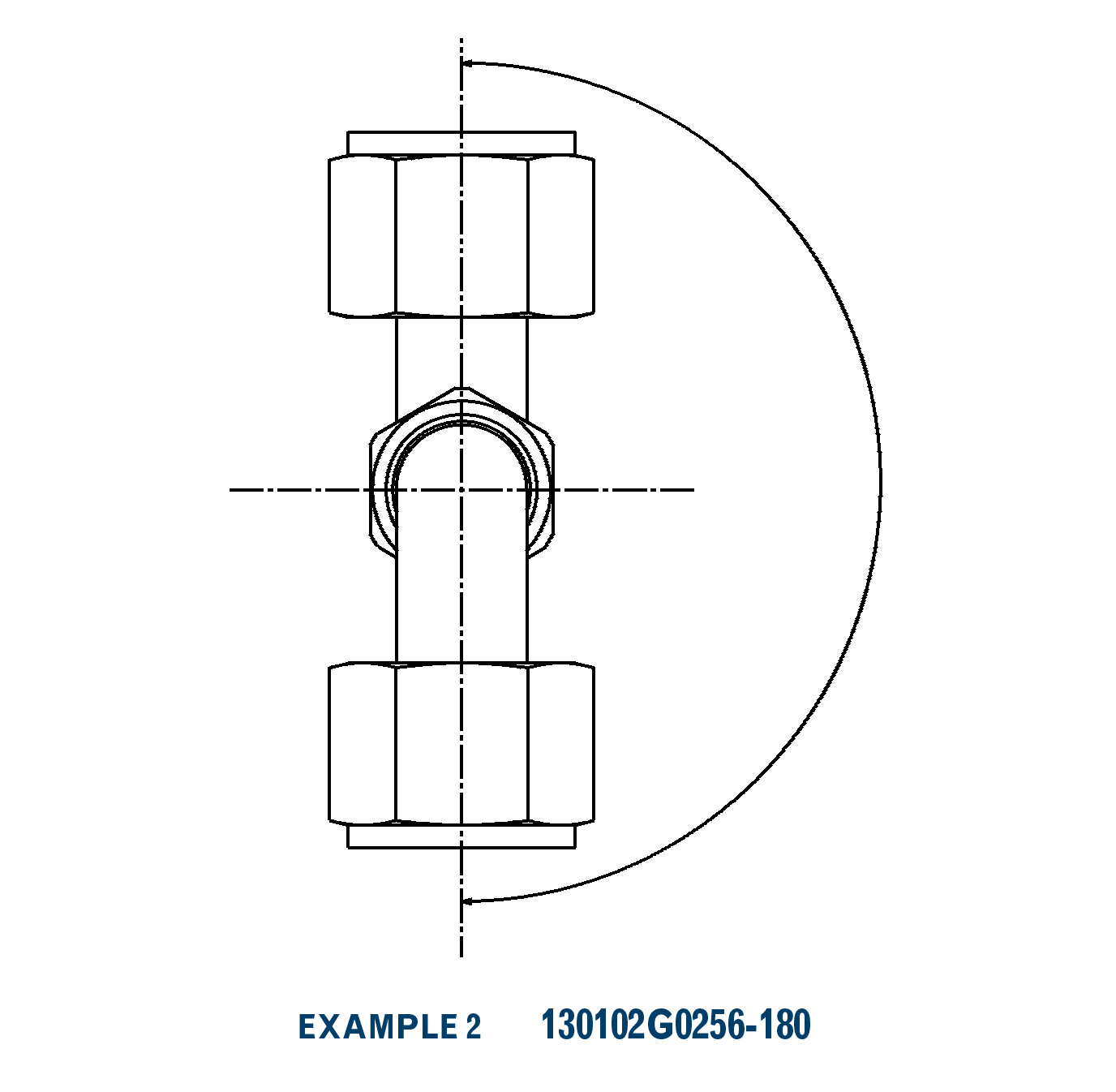

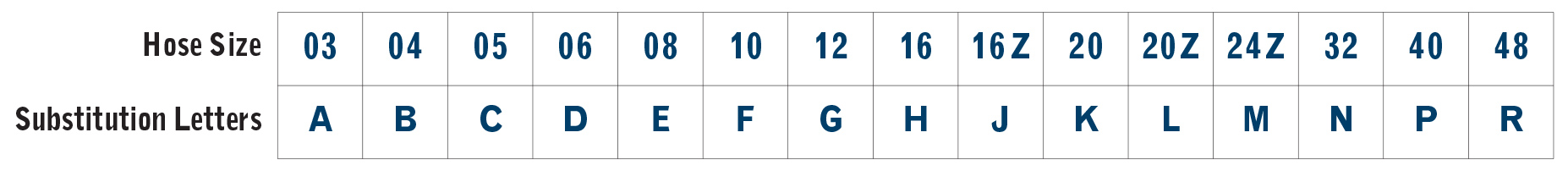

When ordering double elbow hose assemblies, hose size is indicated by a letter instead of number (see table below) and the dash is relocated (or deleted if a special feature code letter is added). Angular orientation between the elbows is expressed in three digits. The angle is measured in degrees counterclockwise from the centerline of the nearest fitting to the centerline of the other fitting as shown in the figure. If the desired orientation is 0 degrees, specify as 000.

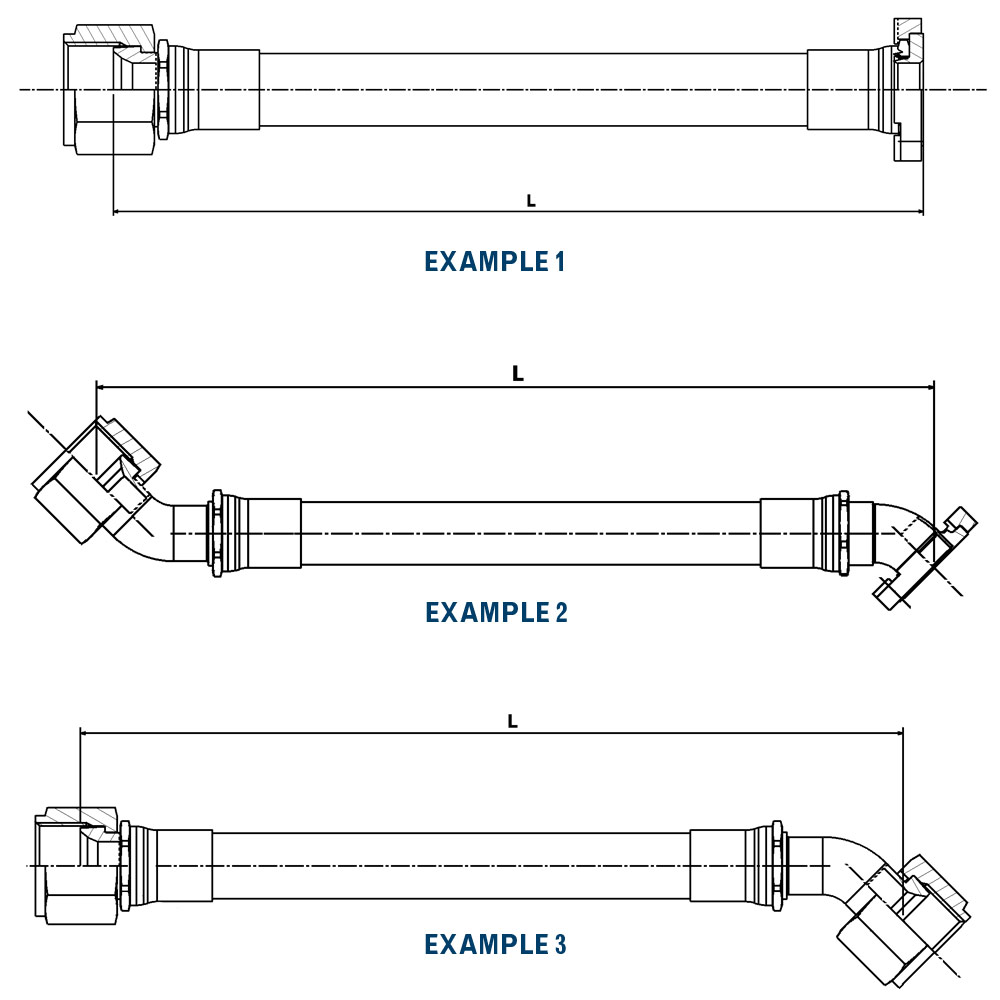

Explanation: Titeflex “130 Series” hose assembly with 45° elbow 38° seat fitting SS at one end and a 90° elbow 38° seat fitting SS at the other end. Hose size is -12 (Nominal inside diameter in 16th inches). Hose assembly length (L) is 25 3/4 inches (025= length in even inches, 6 = length in fractional 1/8 inches. Orientation between the elbows is 180°. The same assembly with a PTFE chafe sleeve would be specified by dropping the dash and inserting the special feature code letter “C”. The number would be then read as 130102G0256C180.

SUBSTITUTION LETTERS FOR HOSE SIZE DASH NUMBER

**Titeflex Trademark and patented product.