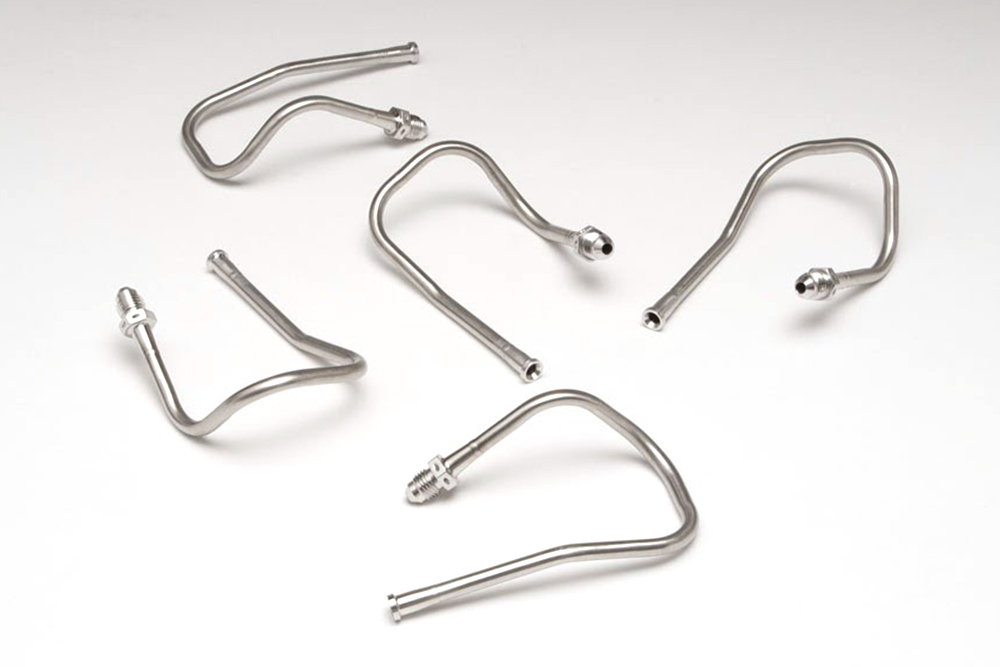

100+ Years of Rigid Tube Bending Expertise

STS Aerospace has over 100 years of rigid tube bending expertise and has evolved in all aspects of precision bending and tube fabrication to become the world leader in aerospace rigid tubes. We excel at working with titanium, CRES, Inconel with diameters ranging from 1/8 to 3 inches and up to 7 feet in centerline lengths. Visit our capabilities pages to see the full portfolio of process offerings that show both processing expertise and continued vertical integration. From simple tubes to manifolds and complex assemblies, we are ready to be your partner in rigid tube fabrication and precision bending.